|

|

|

Cracked exhaust manifolds appear to be quite common on ageing Mk1 MR2s. It is an MOT failure point (an MOT

is a mandatory annual road-worthiness test for vehicles in the UK over three years old). I chose to do the work

myself, and document it on this page, which will hopefully be of use to others.

Symptoms are quite obvious:

a raspy blowing exhaust noise, and strong exhaust fumes around the rear of the car. If your car has these symptoms it may be that the

the connection or gasket between the manifold and cylinder head has failed, or the connection or gaskets between the manifold and the exhaust

pipe has failed. So check these first as they are much cheaper to repair. If you have got a crack in the manifold you will most likely find it

next to number 4 cylinder (the one farthest from the engine bay cooling fan). The common thinking is that the cooling fan cools the right

side of the engine (and hence manifold) more than it does the left, and therefore there are internal stresses in the manifold due to different

levels of heat related expansion, causing the crack. If you do have a crack next to the number 4 cylinder, it will probably look like the one

circled in figure 1. The manifold has heat shields on its inner and outer faces, and you must remove the outer one before you can see the

manifold. Obviously I had done this prior to taking the photograph used in figure 1.

Cracked exhaust manifolds appear to be quite common on ageing Mk1 MR2s. It is an MOT failure point (an MOT

is a mandatory annual road-worthiness test for vehicles in the UK over three years old). I chose to do the work

myself, and document it on this page, which will hopefully be of use to others.

Symptoms are quite obvious:

a raspy blowing exhaust noise, and strong exhaust fumes around the rear of the car. If your car has these symptoms it may be that the

the connection or gasket between the manifold and cylinder head has failed, or the connection or gaskets between the manifold and the exhaust

pipe has failed. So check these first as they are much cheaper to repair. If you have got a crack in the manifold you will most likely find it

next to number 4 cylinder (the one farthest from the engine bay cooling fan). The common thinking is that the cooling fan cools the right

side of the engine (and hence manifold) more than it does the left, and therefore there are internal stresses in the manifold due to different

levels of heat related expansion, causing the crack. If you do have a crack next to the number 4 cylinder, it will probably look like the one

circled in figure 1. The manifold has heat shields on its inner and outer faces, and you must remove the outer one before you can see the

manifold. Obviously I had done this prior to taking the photograph used in figure 1.

To remove the heat shield, and also to remove the manifold itself, you will need to work underneath the car. I have a set of large ramps that

I reverse the car up, but an inspection pit would work even better. Axle stands will probably not raise the rear of the car high

enough off the ground for you to work comfortably underneath.

I chose to renew all the fasteners and gaskets when I did this job. This was for a number of reasons:

My local Toyota dealer is usually happy to accept returns of unused parts, so any you do not use you can get a refund for. I did this with the two manifold to head studs.

If you need to replace the manifold then this is a complete list of what you require if you also choose to replace all the gaskets and fasteners:

Removing the outer manifold heat shield involves removing six bolts using a 10mm socket. Working from above, remove the three bolts on the top of the heat shield. You will have difficulty seeing them, but you can find them by touch easily enough (obviously make sure the exhaust system is cold before trying this). You will need an extension bar for your ratchet handle - a 5" one is ideal. Note that the Haynes manual recommends removing both the distributor and the throttle cable bracket before doing this, but I found that it was not necessary to do so. Then, working from underneath the car, remove the two bolts either side of the manifold just above the joint with the exhaust pipe, and the one in the centre of the manifold about half way up. Hold the heat shield while removing the latter and lower it down gently out of the way, being careful not to snag any piping or wiring as you do so. From underneath the car you will now have a good view of the manifold to exhaust pipe join, so check for carbon deposits which would indicate that the joint is blowing (if it is blowing, and the manifold appears ok, then just follow the sections below that deal with disconnecting the exhaust, fitting new manifold to exhaust gaskets, and reconnecting the exhaust). Have a look at the manifold too, just in case the lower part of it has cracked (unlikely, but check anyway). Now look into the engine bay from above and inspect the manifold. You will probably find it has cracked next to the number 4 cylinder as in figure 1, but if not check the rest of it for cracks. Do this by touch for the area next to number 1 cylinder that is obscured from view by the distributor. If the manifold does not appear to be cracked, and the manifold to exhaust pipe connection appears to be sound, then the manifold to cylinder head gasket is probably blowing. Except for number 1 cylinder end you cannot see the gasket, so inspection is impossible with everything still attached to the car, but if you suspect it is at fault then remove the manifold as detailed below, check the manifold carefully for cracks while it's off the car, renew the gasket and refit the manifold.

You will probably find that you snap the heads off some of the heat shield bolts as they are very weak - so be careful just in case the manifold is ok otherwise you will have to drill the bolt stems out before refitting the heat shield. Given the very high temperatures reached by the manifold, it is wise to refit the heat shields.

The next step is to disconnect the exhaust pipe from the manifold. Three

studs and nuts hold the two together. You will need a deep 14mm socket to

remove the nuts, due to the studs protruding. A 1/2" drive impact socket

works fine. You will also need an extension bar (5" is fine) because two of the

nuts are on the sides of the exhaust pipe, partially hidden by the exhaust

pipe heat shields (there is no need to remove the latter). I used a breaker bar

to slacken the nuts - it is a little unwieldy to use under the car, but it

can be done. I then used a normal ratchet handle to finish off removing the

nuts. As you remove the last nut, be sure you are holding the exhaust pipe

firmly, otherwise it will drop down quite forcefully (it is heavy) and could

damage itself and you in the process. Remove the two circular gaskets.

The Haynes manual advises to remove the exhaust

completely (accomplished by removing the two bolts holding the exhaust to a

bracket near the tailpipes and sliding the whole assembly to the left to clear

the hanging brackets). I didn't do this, choosing instead to tie the manifold

end of the exhaust pipe to the front engine mounting using some stout pieces of

string. There was still plenty of room to work.

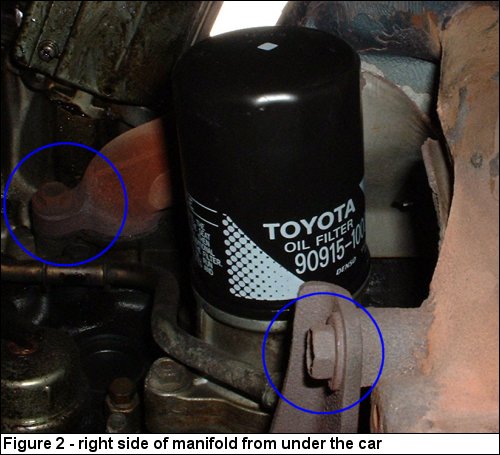

With the exhaust pipe now out of the way, you are ready to remove the

manifold. This is held on with two studs, nuts and washers along the top edge of the joint

with the cylinder head, three bolts along the lower edge of the joint with the

cylinder head, and one bolt securing it to a bracket near to the connection with

the exhaust pipe. The bolt next to number 1 cylinder can be seen circled on the left of figure 2, and the bolt and bracket can be seen circled

at the bottom of figure 2.

The nuts and bolts were easy to slacken, probably because the Toyota specified tightening torque is

just 25Nm. Just to be sure I sprayed each nut and bolt with Plusgas release

agent beforehand. You cannot see the two studs and nuts along the top edge of

the manifold due to their location, but you can find them by touch quite easily

from above. You will need a deep 14mm socket again, and an extension bar (3" is

fine). A wobble bar is useful for the nut between number 1 and 2 cylinders, as

the distributor is very close (a wobble bar is an extension with a beveled male

end that allows the bar to move slightly in the socket, allowing you to clear an

obstruction - they are inexpensive and can be very useful). I used a breaker

bar to slacken the nuts. Although these are a little unwieldy they do allow

you to apply a lot of torque, but in a very controlled manner - exactly what is

required to loosen nuts and bolts without snapping them.

With the exhaust pipe now out of the way, you are ready to remove the

manifold. This is held on with two studs, nuts and washers along the top edge of the joint

with the cylinder head, three bolts along the lower edge of the joint with the

cylinder head, and one bolt securing it to a bracket near to the connection with

the exhaust pipe. The bolt next to number 1 cylinder can be seen circled on the left of figure 2, and the bolt and bracket can be seen circled

at the bottom of figure 2.

The nuts and bolts were easy to slacken, probably because the Toyota specified tightening torque is

just 25Nm. Just to be sure I sprayed each nut and bolt with Plusgas release

agent beforehand. You cannot see the two studs and nuts along the top edge of

the manifold due to their location, but you can find them by touch quite easily

from above. You will need a deep 14mm socket again, and an extension bar (3" is

fine). A wobble bar is useful for the nut between number 1 and 2 cylinders, as

the distributor is very close (a wobble bar is an extension with a beveled male

end that allows the bar to move slightly in the socket, allowing you to clear an

obstruction - they are inexpensive and can be very useful). I used a breaker

bar to slacken the nuts. Although these are a little unwieldy they do allow

you to apply a lot of torque, but in a very controlled manner - exactly what is

required to loosen nuts and bolts without snapping them.

Then working from underneath the car, slacken break each of the three bolts on the lower edge of the manifold to cylinder head joint, and the bolt securing the lower part of the manifold to its bracket. Again I used a breaker bar, which is a little tricky under the car, and in the confines of the engine bay, but is worth it for the reasons given above. I removed the plastic under-car protector plate to give me better access (this needs a 10mm socket with a short extension - be careful, the bolts are very easy to snap). The bolt at the number 1 cylinder end is easy to get at up above the oil filter. The nut at the number 4 cylinder end is more tricky, and you will need to use a 3" extension, optionally with a wobble bar. Even then it is tricky due to the variety of pipes, control cables, engine mounts etc. in that area. You can get to the bolt in the lower edge of the manifold between number 2 and 3 cylinders from either below or above. Either way you will need to do so by touch as you cannot see it due to its location. It is not difficult though; I chose to slacken it from below. Finally, do not forget to slacken the bolt holding the lower part of the manifold to its bracket.

Now that the two nuts and four bolts are loose, you are ready to remove them and

the manifold itself. Remove the two nuts (and their associated washers) from the top of the manifold first (the

studs will probably stay in place and help you by suspending the manifold when

you remove the bolts). Now, from under the car, remove the three bolts holding the

manifold to the cylinder head. Rock the manifold to see if it detaches from the

cylinder head. If it does not, tap it with a rubber or plastic hammer until it

does. It will only come loose at the number 4 cylinder end because of the bolt

and bracket on the lower part of the manifold. Once it is loose, from under the

car, hold the manifold securely with one hand and undo the bolt holding the

lower part to the bracket. Then using both hands, pull the

manifold off the studs and lower it down gently to avoid damaging anything in

the engine bay or yourself. It is quite a heavy item, but easily manageable by

one person. Once the manifold is safely out of the way, remove the gasket from

the cylinder head if it did not come off with the manifold. Mine was stuck to

the cylinder head, but it was easy to work free by hand. Run your fingers around

the whole area covered by the gasket to make sure all remnants of it have been

removed.

Before fitting the new manifold, swap the inner heat shield from the old

manifold to the new one. This is secured by three bolts of the same type

that secured the outer heat shield (see above). There is

no torque setting for these, so tighten them firmly, but not too firm or they

will snap.

Before fitting the new manifold, swap the inner heat shield from the old

manifold to the new one. This is secured by three bolts of the same type

that secured the outer heat shield (see above). There is

no torque setting for these, so tighten them firmly, but not too firm or they

will snap.

The studs stayed in the head when I changed my manifold, so I left them in there and reused them as they felt in good condition (remember you cannot see them - although you could use a small mirror). Removing them would probably be quite difficult if they did not come out with the nuts.

Fit the new exhaust manifold to cylinder head gasket before fitting the new manifold. Note it will only go on one way, so there is no chance of fitting it the wrong way around. Simply slip it over the studs and push it up against the head. This is easiest to do from under the car.

Now you can fit the new manifold. When handling it try not to bash it on the floor because being cast iron it may crack quite easily. Carefully lift it up under the car and hook it onto the studs in the cylinder head. While holding it in place with one hand, fit the bolt to the bracket with the other hand. Do not tighten it yet. Now fit the three bolts to the lower edge of the manifold to head joint but do not tighten them yet either. Then, from above, fit the two nuts to the studs on the upper edge of the manifold to head joint, complete with a washer each. Lightly tighten these using a ratchet. Back under the car, lightly tighten the three bolts on the lower edge using a ratchet. Now, using a torque wrench, tighten the two nuts to 25Nm (as specified by Toyota), then tighten the three bolts underneath to the same torque. Finally, tighten the bolt to the bracket to the same torque.

The final job is to refit the outer heat shield. Manoeuvre it into place from below, fit the two lower and one center bolts from below, and the three upper bolts from above. No torque is specified so tighten them quite tightly, but not too much or they will snap.

Now fire up the engine and you should find that the raspy tone and excess

exhaust fumes have disappeared. When I did this I was alarmed to see smoke

rising from the manifold area, but I soon realised this was poorly aimed Plusgas burning off, and it soon stopped.